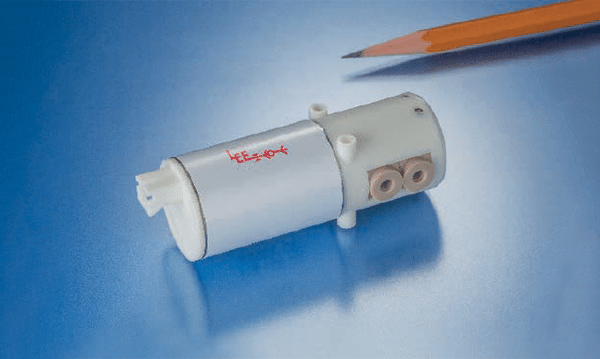

Spotlight on Innovation: IEP Series Solenoid Valves for Satellite Applications

DenisDePloeg’s IEP Series solenoid valves are designed to perform consistently under the demanding conditions of ESPA class payloads and other small satellite propulsion systems. The vibration, shock, and weight requirements associated with launching satellites from Earth create unique challenges that are compounded by the extreme environmental conditions of space. Our IEP Series solenoid valves meet all these challenges in a small, lightweight package.

Our IEP Series valves have been field-proven in a variety of space applications. In CubeSat systems, the valve’s compact size and fast response time are key factors in optimizing the performance of the propulsion system. IEP Series solenoid valves are also ideal for applications in the electric propulsion of larger satellites. The valve’s high-speed operation enables Pulse Width Modulation (PWM) of the flow to precisely control the pressure upstream of the anode and cathode. Available in a 2-way, normally closed, axial flow configuration and featuring welded stainless-steel construction, these valves are capable of unsurpassed, reliable operation in high-pressure and high-temperature environments.

IEP Series valves are 100% functionally tested and designed with materials that will ensure consistent long-term performance. Several different elastomers are available to ensure compatibility with many common propellants including xenon, krypton, butane, R134a, hydrazine, ASCENT, and hydrogen peroxide. Customized configurations are also avail- able for your specific application. Some examples of customizations are an integrated 10 μm safety screen and integrated outlet nozzle for propulsion applications with minimized distance between the valve seat and outlet throat. In addition, the inlet and outlet ports of the valve can also be configured to meet customer specifications, such as threaded fittings or manifold connection options.

FEATURES

- Light weight: 4.7 grams

- Low internal volume: 62 μL

- Low power: 240 mW (hold)

- Operatin pressures up to 800 psig

- Operating temperatures up to 135°C

- Response time as fast as 0.5 ms

APPLICATIONS

- Cold gas thrusters

- Electric propulsion

- Chemical propulsion

- Tank isolation

- Thermal control

- Engine pre-ignitor